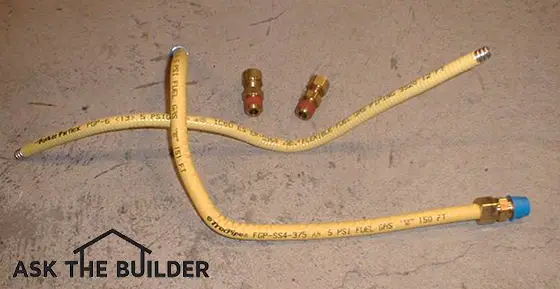

I need to move the line for my stove over 1 foot, since I redesigned my kitchen, and the supply comes in right in the middle of the stove now. I had this professionally done a few months back, and was prepared to have someone come out after I couldn't completely dis-assemble the fitting at the floor, but they have stood me up today, and I am really loathe to pay $100 for 10 min of work, when I know I could do it myself.

Anyway, I have flexible gas line coming in from the crawl space below, into a series of adaptors behind the stove. At issue is the fact that at the bottom is a wide disk used to secure the whole set to the floor. Connected to this disk is a female fitting. When I dis-assembled myself, I found the flexible tubing to be flared-out. This prevented the removal of the female fitting (which itself was attatched to the large mounting disk). Make sense? it looks something like this:

]

][==(

]

the ] is the disk

the [ is the female fitting

the = is the gas line

the ( represents the flare.

Anyway, any suggestions on how to get the female fitting/disk off the flexible line, so I can remove the disk, and then pass the flex-line down and then up through the floor again? Thanks

gk

Anyway, I have flexible gas line coming in from the crawl space below, into a series of adaptors behind the stove. At issue is the fact that at the bottom is a wide disk used to secure the whole set to the floor. Connected to this disk is a female fitting. When I dis-assembled myself, I found the flexible tubing to be flared-out. This prevented the removal of the female fitting (which itself was attatched to the large mounting disk). Make sense? it looks something like this:

]

][==(

]

the ] is the disk

the [ is the female fitting

the = is the gas line

the ( represents the flare.

Anyway, any suggestions on how to get the female fitting/disk off the flexible line, so I can remove the disk, and then pass the flex-line down and then up through the floor again? Thanks

gk

Comment